XPE Foam plant

Located in Italy, MasterPlast is actually European leader of XPE turnkey production plants. Thanks to its 20 years of experience, the company has developped a new approach in cross-linked polyethylene foams and has turned attention to the extra UE markets, exporting its technology in Russia, middle and far-east. Starting from a careful examination of the processes that its customers want to run , MasterPlast provides a service of technical advice, with the aim of perfectly fitting the entire production line with customer's requirements, figuring out the optimal solution in terms of labor and costs in order to obtain the best possible result.

Through a new simpler approach of cross-linked polyethylene foams technology MasterPlast supplies the total package: machinery, know how, products, personnel-training, technical assistance… allowing converters to produce XPE foam in house. MasterPlast analyses your needs and builds for you a tailor-made foaming line.

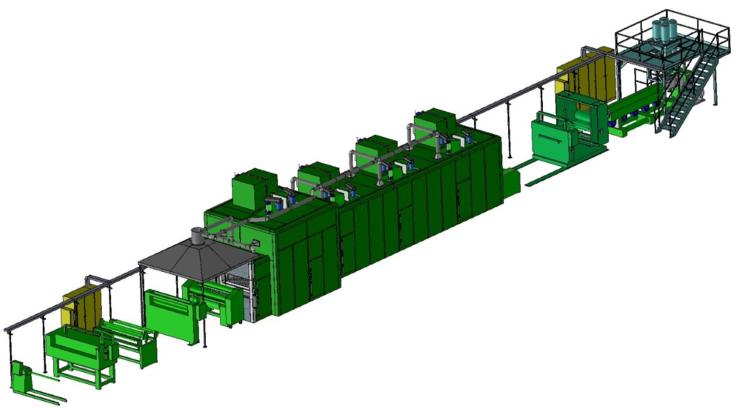

Large XPE foam plant

| Capacity | From 150 to 220+ Kg/h |

| Wideness | From 1,5 to 2+ meter |

| Foam density | From 25 to 250 Kg/m3 |

| Thickness | From 3 to 20+ mm (according to foam density) |

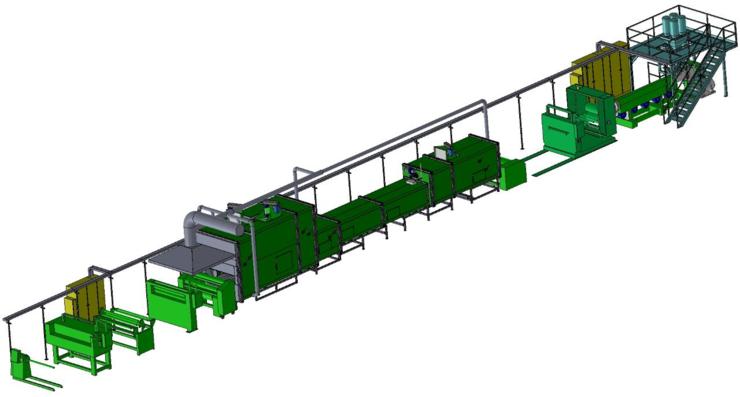

Small XPE foam plant

| Capacity | From 120 to 150+ Kg/h |

| Wideness | From 1,0 to 1,2+ meter |

| Foam density | From 25 to 250 Kg/m3 |

| Thickness | From 3 to 20 mm (accordingly to foam density) |

Why choose a Masterplast plant