Quality

MasterPlast believes that quality is a relationship between realization and expectation because it reveals the level of correspondence between customer’s needs and the supplied product: the more they matches the more we have a quality product.

Through the years, the Company has invested important resources to constantly improving its product quality.

Quality control develops on the entire production process, beginning with an appropriate selection of our suppliers who must satisfy every requisites agreed with the company.

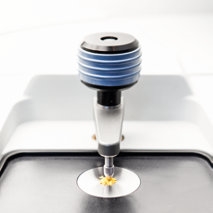

Our lab tests every incoming raw material granting or rejecting its use in the production process

Thanks to the creation of an internal software and a barcode scanner, we can ensure the traceability of all our products. Each lot of raw material has a logistic label, a sort of electronic identity card where we add information following the product from warehouse to the final customer.

Our lab analyzes each lot of masterbatches prior to give the definitive approval to delivery.